Foundry

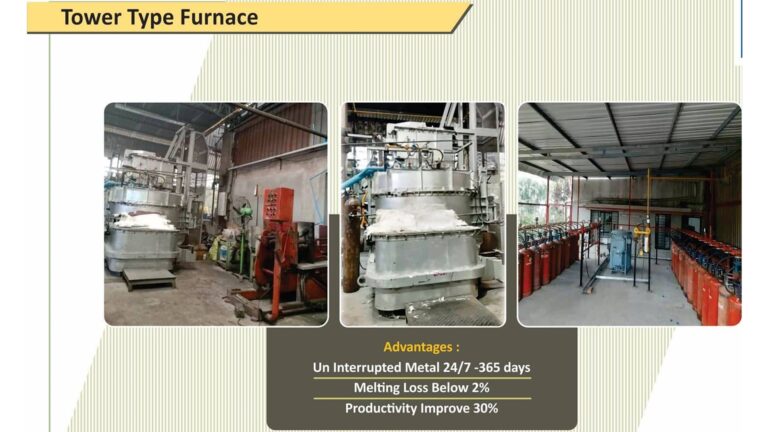

- To brief, the foundry has 2 different lines, in one line we manufacture high volume parts in a new technology Tower furnace which gives uninterrupted metal continuously & consistently 24×7,365 days a year. The GDC platform on the Tower furnace has 22 machines (static & Tilt pour) & GDC dies running to full capacity manufacturing 4MT a day (100 MT per month). Here we manufacture parts weighing 110 grams to 500 grams & volumes of 10,000 nos to 100,000 nos per month

- The other line comprises of 30 machines (static & tilt pour) to make castings in batch sizes of 50 to 5000 nos per month manufacturing 100 MT per month. Here we manufacture parts weighing from 1 kg to 30 kg & length of 1000 mm & all cored castings with shell cores which are hollow to reduce weight & improve the quality & cost.

Foundry Infrastructure at a glance

| Line no 1 | Nos | Line no 02 | Nos |

| Tower Furnace | 1 | Melting Furnace | 04 |

| Belt polishing | 08 | Holding Furnacce | 08 |

| Gate cutting | 05 | GDC Static | 22 |

| GDC Static | 14 | GDC Tilt Pour | 08 |

| GDC Tilt pour | 08 | Gate Cutting & SPM | 04 |

| Heat Treatment(T5&T6) | 02 | Belt Polishing | 06 |

| (100 Kg Capacity) | 01 | HT(1000kg)(T5 & T6) | 02 |

| (500 kg capacity) | 01 | Thermal Decoring (500 kg) | 01 |

| Shot Blasting | 02 | Millipore | 01 |

Previous

Next

Machine Shop

The machine shop is also built with a LEAN layout by doing value stream mapping & maintain a sequential flow for better productivity & consistency. The machine shop comprises of 10 CNC Machines & 17 VMC machines which are well equipped with 4th axis & rotary & linear pallet changers as per the part requirement. This is clubbed up with the latest IMPREGNATION plant with pressure vessel & rotary wash for better sealing & cleaning purpose. There are 9 leak testing machines to check for any leak in casting with pressure bar at 140 PSI. Similarly dedicated casting cleaning machines are provided after machining & before packaging to send cleaner & dust free parts to customer. All cored parts are tested with Millipore before shipments.

| Machine shop Machining | Nos |

|---|---|

| CNC Turning | 10 |

| VMC with 4th axis | 15 |

| VMC Rotary pallet changer | 01 |

| VMC Linear pallet changer | 01 |

| SPM Machines | 06 |

| Drilling & chamfering | 04 |

| Cleaning Machines | 02 |

Previous

Next

Inspecction Area

Previous

Next